Gravel is a loose collection of rock fragments that range in size from 2 millimeters to 64 millimeters in diameter. This versatile construction material forms naturally through weathering and erosion processes or is manufactured by crushing larger rocks in quarries. Whether you’re planning a driveway project, foundation work, or landscaping enhancement, understanding what gravel is and how it functions can help you make better material choices for your construction needs.

Most gravel consists of quartz particles because quartz remains hard, chemically stable, and resistant to breaking along natural fracture lines. This durability makes gravel an essential building material that offers excellent drainage properties, affordability, and long-lasting performance across numerous applications.

How Gravel Forms and Its Natural Origins

Gravel develops through two distinct processes that determine its characteristics and performance qualities. Natural gravel forms when larger rocks break down over time due to weathering, wind, water, and ice action. Rivers and streams transport these rock fragments, rounding and smoothing them as they travel downstream, creating the rounded pebbles commonly found in riverbeds and beaches.

Manufactured gravel comes from quarries where workers use crushing machines to break large rocks into smaller, angular pieces. This crushing process creates jagged edges that help the pieces lock together, making crushed gravel ideal for construction applications requiring stability and compaction. The source rock can include granite, limestone, sandstone, basalt, and other durable materials.

The formation process directly affects how gravel performs in different applications. Natural gravel with smooth, rounded edges works well for decorative purposes but may shift under heavy loads. Crushed gravel with angular edges provides better interlocking and stability for driveways, foundations, and road construction projects.

Read More = How Much Does a Dump Truck Load of Gravel Cost in 2025? Complete Pricing & Buying Guide

Different Types of Gravel and Their Applications

Various gravel types serve distinct purposes based on their size, shape, and composition. Each type offers unique benefits for specific construction and landscaping projects that match particular performance requirements.

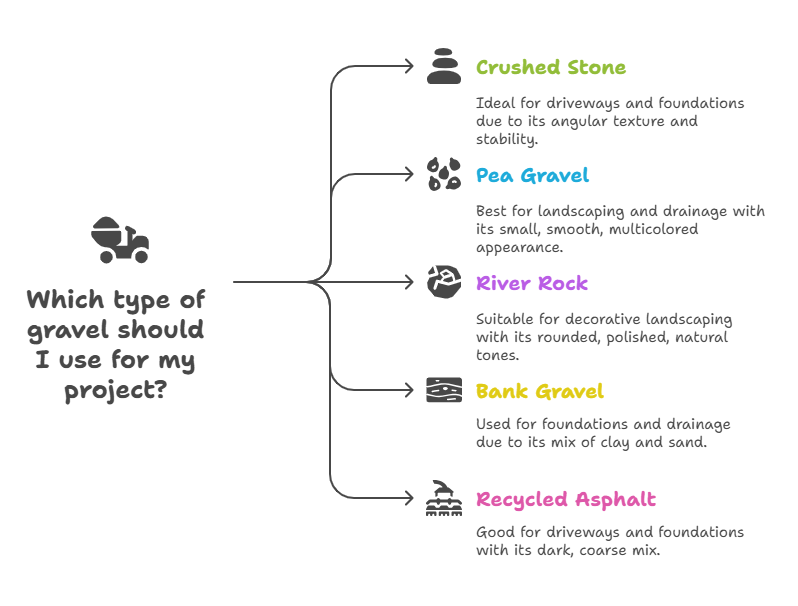

Crushed stone represents the most common manufactured gravel type used in construction work. Workers create it by crushing larger rocks into angular fragments that range from small chips to several inches in diameter. The angular edges help pieces lock together, creating stable surfaces for roads, driveways, and foundations. Crushed stone provides excellent drainage while maintaining structural integrity under heavy loads.

Pea gravel consists of small, rounded stones about the size of garden peas, typically measuring 3/8 inch in diameter. Its smooth texture and variety of colors make it popular for landscaping projects, walkways, and decorative applications. However, pea gravel shifts easily under weight and requires proper edging or stabilization for driveway use.

River rock includes naturally rounded stones shaped by water erosion over time. These smooth, polished stones work well for landscaping features, garden beds, and water features where appearance matters more than structural stability. River rock comes in various sizes and natural colors that complement outdoor spaces.

Bank gravel naturally occurs in and around rivers and streams, mixed with sand and clay. Also called bank run or river run, this material provides good compaction properties for road bases and driveway foundations. The mixed composition helps it pack down firmly while still allowing proper drainage.

Read More = How Much Is a Ton of Gravel? 2025 Price Guide, Cost Factors, and Buying Tips

Size Classifications and Industry Standards

The construction industry uses standardized size classifications to ensure gravel meets specific project requirements. The Udden-Wentworth scale provides the most widely accepted grading system for gravel and other sediments used in construction work.

According to this classification system, gravel includes particles from 2 millimeters to 64 millimeters in diameter. Fine gravel ranges from 2 to 6.3 millimeters, medium gravel spans 6.3 to 20 millimeters, and coarse gravel extends from 20 to 63 millimeters. Materials larger than 63 millimeters fall into cobble and boulder categories.

The size classification affects how gravel performs in different applications throughout construction projects. Smaller gravel provides better surface finish but may lack stability for heavy-duty uses. Larger gravel offers superior load-bearing capacity and drainage but creates a rougher surface texture. Choosing the right size ensures your project meets both functional and aesthetic requirements.

Professional specifications often use numbered grades like #57 stone (3/4 inch) or #411 stone (3/4 inch down to dust) to indicate specific size ranges and compositions. These standardized grades help contractors and homeowners calculate gravel quantities and select appropriate materials for their specific construction needs.

Construction and Infrastructure Applications

Gravel serves as a fundamental building material in construction projects worldwide. The construction industry consumes approximately 42% of all gravel production for concrete aggregate alone. This massive demand reflects its essential role in creating durable infrastructure systems.

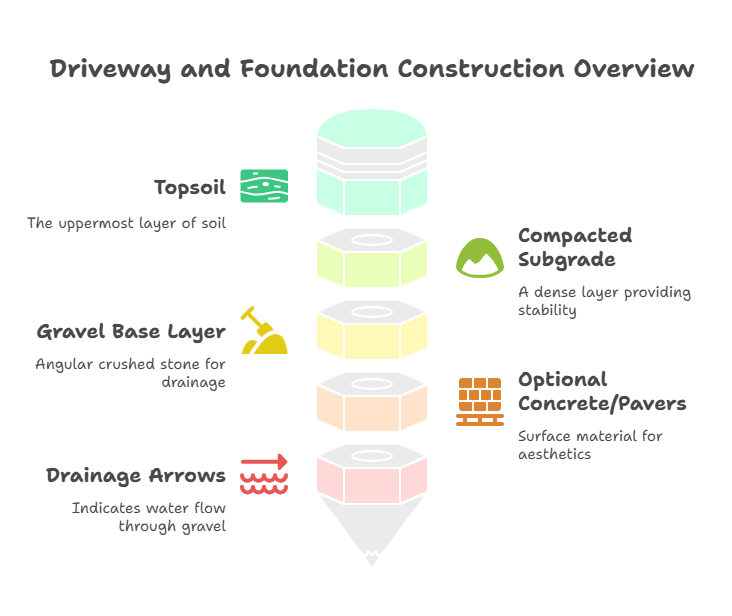

Foundation applications rely heavily on its drainage and load-bearing properties. Builders place gravel bases under concrete slabs, building foundations, and retaining walls to provide stable support and prevent water accumulation. The angular nature of crushed gravel helps distribute loads evenly while allowing water to drain away from structures.

Road construction uses enormous quantities of gravel for base layers and surface materials. About 20% of production goes toward road bases and coverings, creating the stable foundation that supports asphalt and concrete highway surfaces. Gravel roads in rural areas use this material directly as the driving surface.

Concrete production incorporates gravel as coarse aggregate, which provides strength and reduces the amount of cement needed. The angular shape of crushed gravel creates better bonding within concrete mixtures compared to rounded natural stones. This makes structures stronger and more durable over extended time periods.

Drainage systems benefit from natural permeability and filtering properties that prevent water accumulation. French drains, septic system drain fields, and stormwater management systems use gravel to allow water flow while filtering out sediments and pollutants. The void spaces between pieces provide pathways for efficient water movement.

Read More = How Much Does a Truck Load of Pea Gravel Cost and What to Consider Before Buying?

Landscaping and Decorative Uses

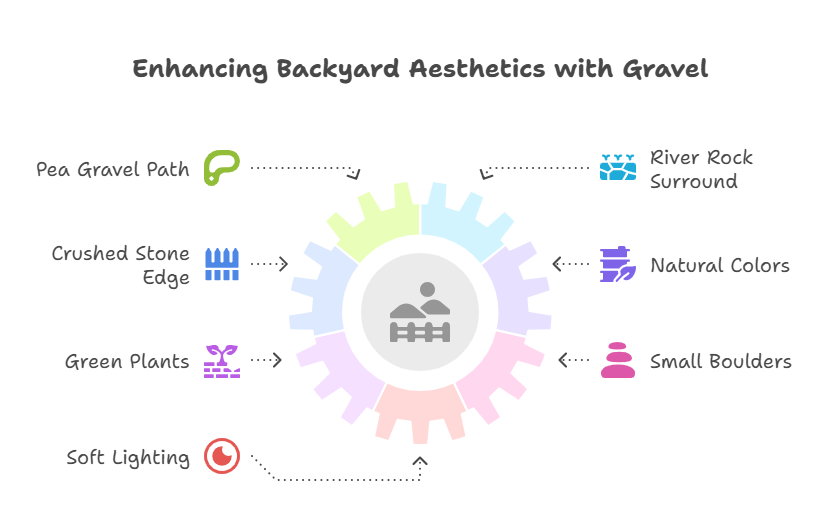

Gravel offers homeowners and landscapers attractive, low-maintenance options for outdoor spaces. Its natural appearance, variety of colors, and excellent drainage make it suitable for numerous decorative applications that enhance property value.

Pathway creation uses gravel to establish attractive walkways that complement garden designs perfectly. Pea gravel and small decorative stones provide comfortable walking surfaces while preventing mud and puddles during wet weather. The permeable nature of gravel paths helps manage stormwater runoff naturally without costly drainage systems.

Garden mulch applications take advantage of ability to suppress weeds while retaining soil moisture effectively. Unlike organic mulches that decompose, gravel provides permanent ground cover that never needs replacement or refreshing. This makes it particularly valuable in water-wise landscaping and xeriscaping projects that reduce maintenance requirements.

Driveway surfaces can use various gravel types depending on traffic levels and aesthetic preferences desired by property owners offer affordable alternatives to concrete or asphalt while providing excellent drainage and easy maintenance over many years of use.

Water features incorporate river rock and decorative gravel to create natural-looking streams, ponds, and fountains that blend seamlessly with landscaping. The smooth texture of river rock prevents injury while its natural colors complement water and vegetation beautifully. Gravel also provides biological filtration in pond systems.

Read More = How Much Gravel Can a Dump Truck Hold?

Choosing the Right Gravel for Your Project

Selecting appropriate gravel requires understanding your project’s specific needs, local conditions, and performance requirements for long-term success. Several factors influence the best choice for any construction or landscaping application.

Traffic loads determine the size and type needed for stability under expected use patterns. Heavy vehicle traffic requires angular crushed stone that compacts firmly and resists rutting over time. Light foot traffic or decorative applications can use smaller, rounded materials that prioritize appearance over load-bearing capacity.

Drainage requirements influence selection for areas with water management needs and seasonal weather patterns. Larger sizes provide better drainage but may sacrifice surface smoothness for pedestrian comfort. Projects requiring both drainage and compaction often use graded mixes that combine different sizes for optimal performance.

Climate considerations affect how materials perform in different weather conditions throughout the year. Freeze-thaw cycles can destabilize poorly chosen options, while areas with heavy rainfall need materials that provide good drainage without washing away during storms.

Aesthetic preferences matter for visible applications like driveways and landscaping that impact property appearance. Materials come in numerous colors and textures that can complement or contrast with existing hardscaping and architecture to create desired visual effects.

Read More = Gravel Calculator for Driveway

What size gravel works best for driveway construction?

Medium to large sizes between 3/4 inch and 1.5 inches work best for driveway applications. This size range provides good compaction and stability while preventing stones from getting stuck in tire treads during regular use. Crushed stone #57 (3/4 inch) remains particularly popular because it compacts well while maintaining drainage properties that prevent water accumulation. Avoid materials smaller than 1/2 inch for driveways as they tend to shift under vehicle weight and can embed in tire surfaces.

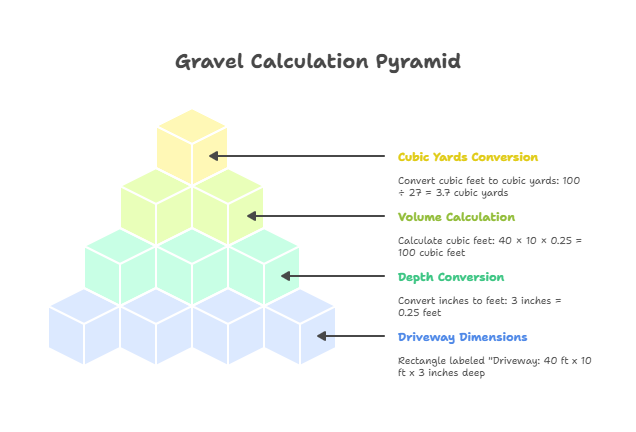

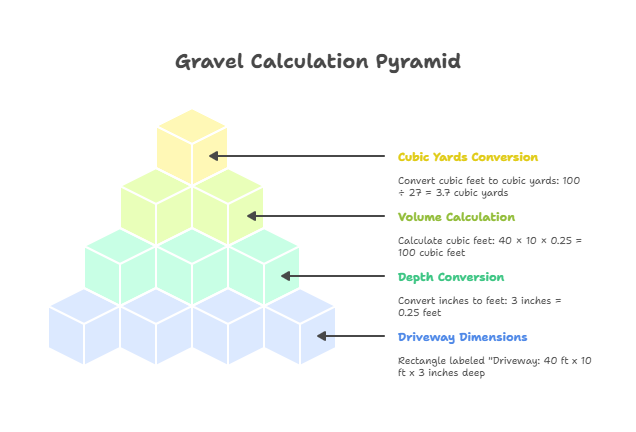

How do I calculate the amount needed for my project?

Calculate needs by measuring the area length times width times depth in feet, then dividing by 27 to get cubic yards required. As a general rule, one ton covers approximately 100 square feet at 2 inches deep for most standard applications. For driveways, plan for 3-4 inches of compacted depth, while walkways typically need 2-3 inches for proper performance. Account for compaction and waste factors when determining final quantities to order.

What distinguishes gravel from crushed stone materials?

The main difference lies in their formation process and resulting shape characteristics. Natural gravel forms through weathering and erosion, creating rounded stones with smooth surfaces ideal for decorative uses and areas where appearance matters most. Crushed stone is mechanically produced by crushing larger rocks, creating angular edges that interlock better for structural applications like foundations and roads. Both serve different purposes, with crushed stone preferred for load-bearing applications and natural options chosen for landscaping projects.

Read More = Concrete Aggregate Calculator

Can I use gravel for foundation drainage systems?

Yes, it provides excellent drainage around foundations when properly installed with appropriate materials and techniques. Use clean, angular pieces without fines (small particles) to ensure good water flow away from foundation walls. Install materials at least 6 inches wide along foundation walls and slope them away from the building for effective water management. Avoid using types with high clay or silt content as these materials can trap water rather than drain it effectively.

How long will a gravel driveway last with proper care?

A properly installed driveway can last 20-30 years or more with regular maintenance and appropriate material selection. The lifespan depends on factors including traffic volume, climate conditions, material quality, and maintenance frequency throughout its service life. Annual maintenance typically involves adding fresh material, grading the surface smooth, and addressing any drainage issues that develop. Well-maintained driveways often outlast concrete alternatives in areas with freeze-thaw cycles.

Is gravel an environmentally friendly construction material?

It offers several environmental advantages including natural permeability for stormwater management, recyclability potential, and abundant availability from local sources. However, extraction processes can impact local ecosystems and water quality if not properly managed. Choose locally sourced materials to reduce transportation emissions, and consider recycled options like crushed concrete when available for your project. Its long lifespan and minimal processing requirements generally make it more environmentally friendly than manufactured alternatives like concrete or asphalt.

What regular maintenance does gravel require for optimal performance?

Regular maintenance involves periodic raking to redistribute stones evenly, adding fresh material to maintain proper depth, and ensuring adequate drainage continues working effectively. Spring maintenance typically includes filling low spots and grading the surface smooth after winter weather damage. Remove weeds promptly and address drainage issues before they cause erosion problems that require expensive repairs. Most surfaces need fresh material added every 2-3 years, depending on traffic levels and local weather conditions.